Coop’s Concerto

The local craft brewer has evolved with the law, market forces, and now, a grand vision.

COOP Ale Works is preparing its third act.

MOVEMENT ONE

COOP entered craft beer early, by Oklahoma standards. After home brewing and informal beer tastings in the back room of Cheever’s, research trips to two dozen craft breweries around the nation, and several feasibility studies, COOP’s formal operations began in 2009 with a 7 barrel system on NW 51st and Western under the leadership of Daniel Mercer, JD Merryweather, Mark Siebold, brewer Chase Healey (who later founded the craft breweries Prairie Artisan Ales and American Solera), and soon thereafter brewer Blake Jarolim.

As with most small businesses in burgeoning local industries, COOP’s early growth period was full of long days, frustration, and its share of successes for its three production staff. Prior to the passage of Senate Bill 424 in 2016, which allowed full-strength alcohol to be sold at brewers’ onsite taprooms, COOP’s ability to generate revenue was limited to its distribution agreements, and success rested on its raw ability to produce. “For three to four years, our biggest priority was just survival,” recounts Daniel Mercer, CEO. As the second paid employee, head brewer Blake Jarolim remembers it clearly. “We were a really close group of friends. It felt really cool to see everyone be a part of it and chip in. But, as time wore on and workload increased, there were 12-hour days that would go by without talking. The only thing that was holding up selling more beer was the limit of how much we could produce in a day. It was a super exciting and challenging time.” COOP found its core production team and lead product: F5, a hoppy India Pale Ale, which constitutes over half of its beer sales. It remains the best-selling craft beer in Oklahoma, with only Prairie Artisan Ales, another pre-SB 424 brewer, rivaling COOP in its breadth of nationwide distribution.

By 2014, the company had outgrown its production space and moved to its current location, at 4745 Council Heights Road in SW OKC. With the move came a change in culture. “It became, ‘How can we promote excellence and remove hurdles from people’s development and allow them to do their job to the best of their ability?’” Jarolim reflects.

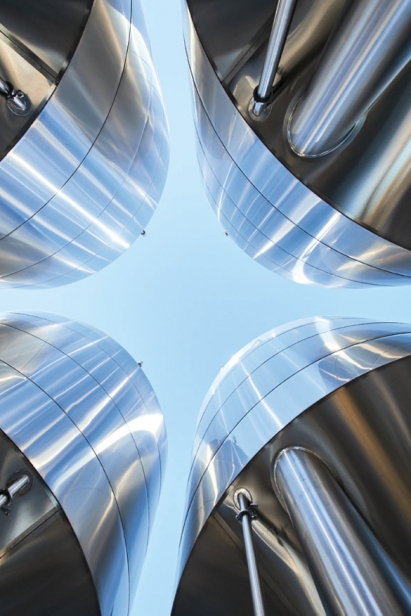

By the end of 2018, State Question 792 and Senate Bill 383, which allowed Oklahoma grocery and convenience stores to sell high point beer, passed — and COOP had built an executive management team, a dedicated HR team, and a larger supply team staff to refine organization and production procedures. A $2 million investment in equipment allowed production staff the capacity to focus on creativity. COOP had doubled its sales in a year, and would double them again the following year.

In a sign of cultural and industry prominence, the owner of Tulsa’s Marshall Brewing Company, Adam Marshall, called COOP in 2019 with a story. One of Marshall’s patrons was in the hospital and was expected to pass away soon. One of his last wishes was to have DNR, a COOP produced Belgian style dark ale and the patron’s favorite beer, be the last liquid he consumed. COOP staff delivered DNR to his room by hand.

MOVEMENT TWO

COOP’s second phase was its creation of COOP Beverage Works in late 2020 and a co-packing partnership with then OKC food and drink titan SONIC Drive-In. The relationship produced SONIC Hard Seltzers in the spring of 2021, which found immediate success with over 255,000 case equivalents sold in six states that year. The hard seltzer quickly represented over 60% of COOP’s total production output. Originally distributed in six states, SONIC Hard Seltzer is now available in 75% of the nation. Further, COOP Beverage Works recently partnered with Chicago-based juice brand Tampico to create a line of hard punches to help quench the seemingly endless thirst of day drinkers.

This period of rapid growth and revenue meant significant organizational change. COOP moved corporate offices to the Pontiac Building on Broadway in downtown OKC. Its seven employees in 2017 had expanded to 25 in 2019, and over 60 by mid-2022.

When talking with other brewers in Oklahoma City, it’s not uncommon to hear the phrase “COOP money” or some derivation. It’s spoken out of admiration and, at times, envy. Brewers established after SB 424 and State Question 792 often opened breweries with attached taprooms first, their efforts equally guided toward community development as much as craft beer production and distribution. This business plan relied on higher margins in the taproom to offset the lower production volume, compared to brewers like COOP and Prairie. The result is two primary categories of Oklahoma brewers: the smaller community taproom-based brewers whose survival is determined by their local reach and community engagement, and the larger production and distribution business which produces consistent staples and supplies the capital for their business leaders looking to expand.

In the wake of the five-year explosion of craft breweries across Oklahoma post-SB 424, growing from 20 brewers in 2016 to 76 in 2021, the market for taproom attendance has experienced a plateau, with craft breweries having to find their respective niches. A sense of comparison is inevitable as the number of local taprooms finds its homeostasis-like balance and distribution-focused brewers expand their reach outward.

MOVEMENT THREE

COOP’s third iteration is marked by its scope of vision. COOP purchased the 89,000-sq-ft and 8.5 acre WPA-era National Guard Armory complex located at 200 NE 23rd Street. It plans to expand its brewing operations to a 60-barrel brewhouse sitting in a 4,000-sq-ft production space, a taproom, a boutique hotel, 11,000 sq ft of villas, a 4,000-sqft restaurant, a basement speakeasy, pool club, beergarden, and event spaces, all projected to open by 2026. It will take a near-tripling of employees to support the effort. “We’ve always wanted to bring the brewer back to the core of the city. It will put us in the forefront of hospitality. There will be no other destination brewery venue like that in the world. This will be the cherry. It gives us a stage and the opportunity for people to interact directly with the brand, not just a secondhand brewery or taproom experience,” Daniel asserts. “We’ll also have a lot of new toys. We’ll have more piloting capabilities. We’ll be able to showcase our archive through the speakeasy,” Blake chimes in.

It’s fair to ask whether COOP Ale Works is a brewer or evolving into something more complex and broad.

FINALE

According to Daniel Mercer, the operation is a business. “My primary pursuit has been to treat this as a business first and a brewery second. That puts us in a very shallow minority of breweries in the United States.” As COOP shifts into the hospitality world, this mentality becomes increasingly clear. “We’re looking for people with a problem-solving mindset, that are really adaptable, and want to be involved in growth and building systems,” says Lauren Gerfen, COOP’s HR director. Daniel doubles down, “I’m in the business of being open-minded. So much of that is through continuing education and mentoring. How do I give people the ability to discern, develop, and be open-minded about how we approach our operation? That’s my focus.”

COOP Ale Works is on track to produce 16,000 barrels or roughly 500,000 gallons of beer this year. COOP Beverage Works expects to produce an additional 1,100,000 case equivalents or roughly 80,000 gallons of SONIC and Tampico branded products during the same period. Will its third movement of creating a hospitality haven for tourists, events, and beer lovers previously unknown in the United States see the same success?